Green Minerals

Capturing and storing CO2 in materials by means of mineralization

Website: https://www.green-minerals.nl/

Country HQ: Netherlands

Founded Date: 2008

Industry: CO2 capture & utilization

Applications: Paper, Concrete, Polymers

Founder: Pol Knops

Pol at work in the lab

YOUR JOURNEY TO FOUNDING

After my studies in physics, I worked for a few companies in the field of renewable energy and waste handling, always busy with developing novel processes. The idea behind Green Minerals came 12 years ago, and it was a tedious process. At that time there were some people interested in olivine—a rock-forming mineral—and I happened to know a big promoter of olivine, who asked me for a physical and chemical perspective to be included into their business plan. So I started looking into it and found out there were two ways of using this material. The first one is using olivine in its natural state in several applications, which takes a multi-year process. That’s the one most people were focusing on. As i.e. GreenSand.

However, I found quite some research about olivine done in the United States in the 80s, which was arguing that, given that it’s a chemical process, you can increase the reaction rate by increasing temperature and pressure. In that way, you can have a tremendous increase in the speed of the process. At that time, the research was stopped due to few reasons: the economic crisis, climate change was less on the agenda, and the fact that they thought a high-pressure/high-temperatures process was quite challenging. My background was working for 12 years at a high-pressure/high-temperature process, so I knew how to achieve those conditions. That was the reason to start looking into olivine and get things started at Green Minerals.

THE FOUNDING MOMENT

I found a partner—nowadays we’d call him an angel investor—and together we started simply by making our own reactor and installing it in my partner’s basement. We started by doing and, while talking to quite some people, we came in contact with the University of Leuven, in Belgium. A professor there liked the idea and told us ‘if you bring over the equipment, I will involve the students and we can do this on a better basis’. So we got the reactor out of the basement, put it into a car, and drove to Leuven. Then it went much faster, because there was more access to lab equipment and a better academic network so that we could do this research on a greater scale. A few students did a master thesis about that, one of them also wrote his PhD, which allowed us to learn the process better. That went on for 3 years.

“We started simply by making our own reactor and installing it in my partner’s basement”

The Reactor

In the meantime, I was doing some consultancy, because it was still unpaid. Then, about 7-8 years ago, we signed a collaboration project with two bigger companies, which allowed us to get better products and pay ourselves some limited salary. After a Research Phase I with these companies, we got some reasonable results but they nevertheless decided to stop the project because they thought it wouldn’t be economically viable. They thought we were making low-value products with CO2 and olivine, and for the CO2 you would have to pay. It was a pity because we had just started, and after another four years on the project, my partner also lost interest, because he was expecting much faster results.

I continued because, even if economically feasible in that specific case, I knew there might have been different markets, that the CO2 price will increase and that climate change would be higher on the agenda. This was even before the Paris Agreement, so you can imagine it was a different playground. About two years ago, I joined an incubation program to learn more about the business side and on how to attract industrial interest. At the end of it, I signed a research project with the University of Aachen and Heidelberg Cement, which set me back on track.

THE INNOVATION

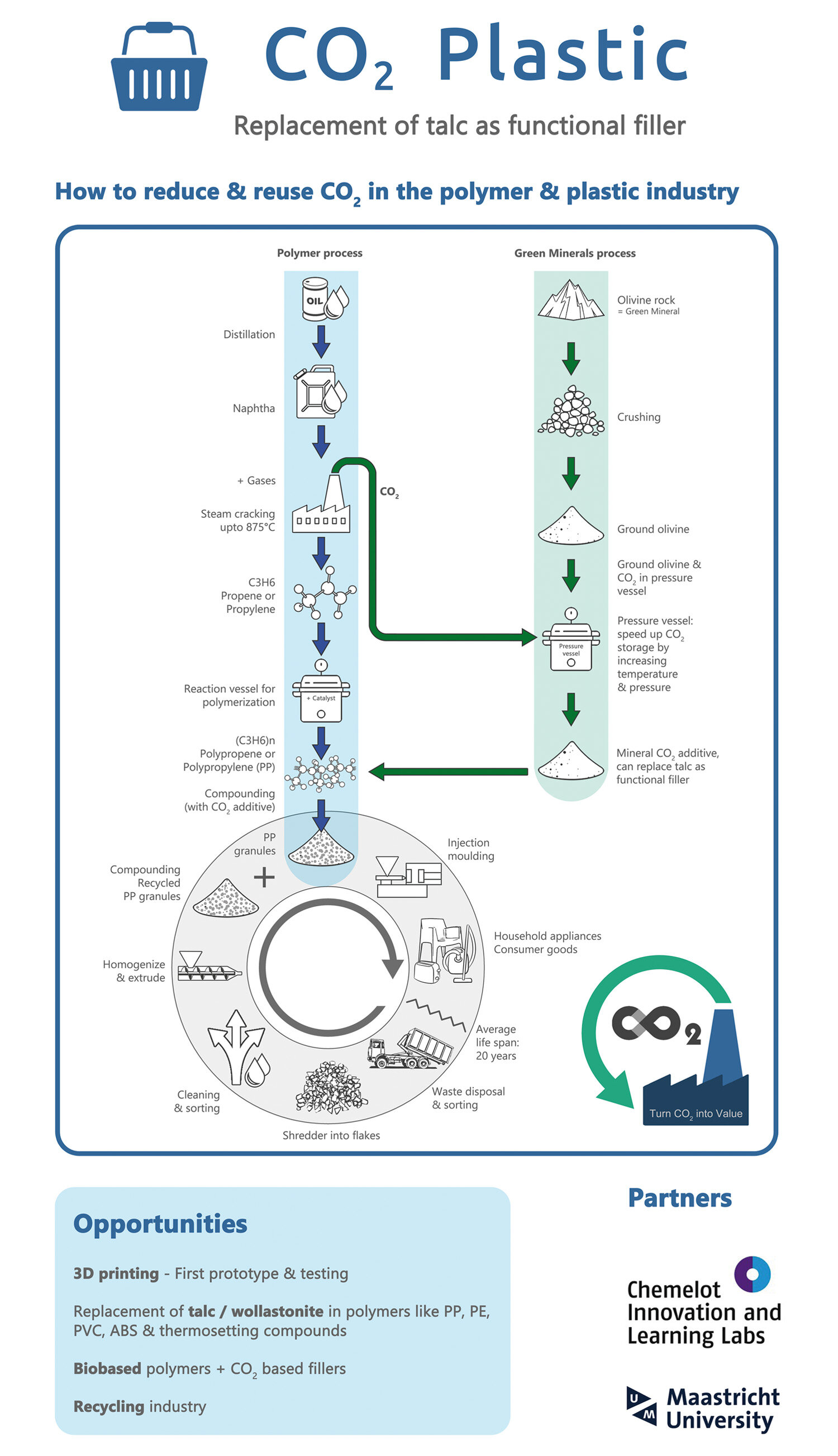

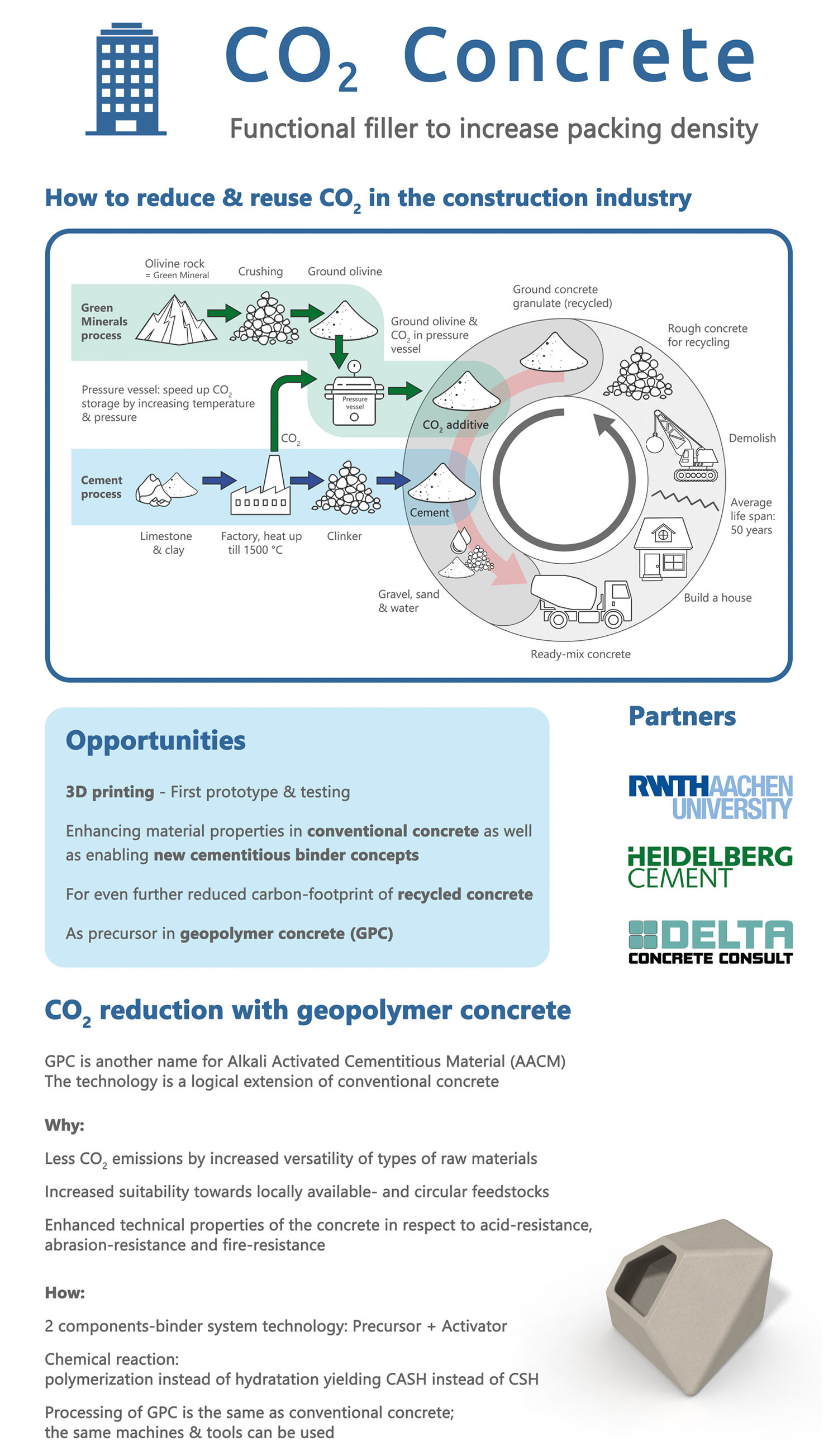

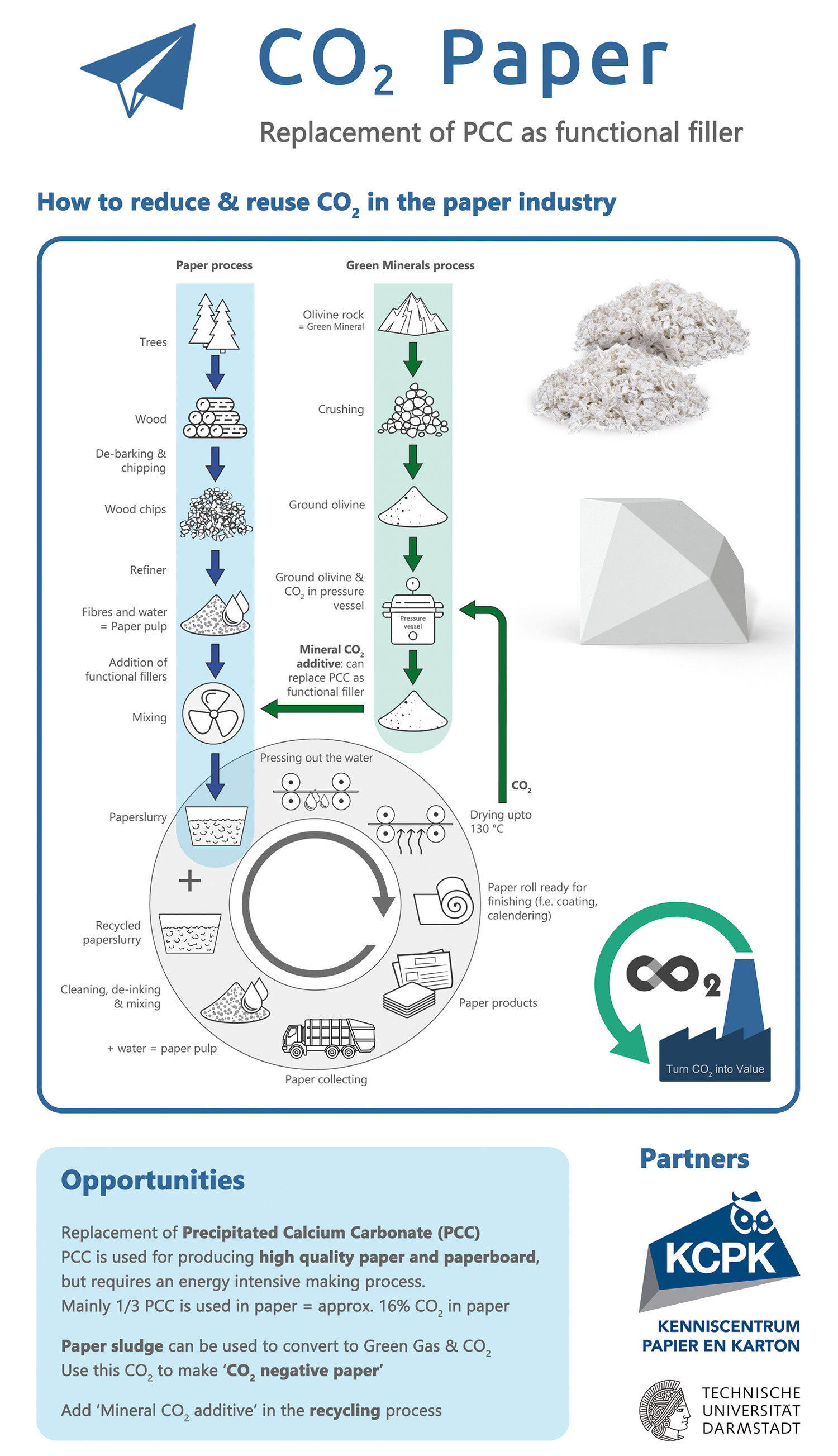

Our applications are based on a process where CO2 is captured and stored in materials by means of mineralization. CO2 is approached as a raw material which reacts with olivine: a rock-forming mineral that binds CO2. Chemically wise, CO2 is acidic, while Olivine is basic, so they react with each other. That’s also happening in nature over a timespan of several years: that’s how lime is formed. When the two react, they form a carbonate, a sort of fine powder. The problem is that the traditional way to make such a fine powder requires a high level of energy, so I thought: what do not use it to replace other products?

“Our applications are based on a process where CO2 is captured and stored in materials by means of mineralization”

Semi-finished products

Which value applications did you explore for the powder ?

I looked into what were the possibilities and I found out that if you manufacture paper, you typically need a huge amount of lime, which is quite expensive. I thought we could replace lime with this new material, so we made the first paper that is CO2 negative. It’s bio-based paper and CO2 based filler. Another application is polymers, where we typically use quite a lot of lime as functional filler. And another one is concrete, where there is also a lot of lime.

The idea in all these applications is to replace lime with this material, so to get revenues not only from the CO2 but mainly from the products. If you need two tons of olivine and one ton of CO2 to make 3 tons of end product, in this case you get money from the 3 tons of end product and not only the CO2. It’s quite difficult because we are talking to companies that are making paper with the same process for more than 100 years, and you have to convince them that they can use a completely different feedstock.

“We are talking to companies that are making paper with the same process for more than 100 years, and you have to convince them that they can use a completely different feedstock”

How do you get access to the feedstocks - both the CO2 and the olivine?

The olivine is commercially available. There are 3-4 olivine mines in Europe, where they use olivine for steel production, so you can simply buy it. I didn’t spend time finding olivine, I knew it was widely available, that’s also my reason to choose olivine because it was already mined and available. About the CO2, there are so many people working on CO2 capture and CO2 concentration, so I didn’t spend too much time on that. At this point in time, I still got it in a bottle because I need a limited amount, but if you want it in a bigger amount, you can have it from flue gases, or direct air capture. If you are making paper with this material, you need both, the bio-based fibers and the CO2-based fillers.

If you are talking about cement, it produces a lot of CO2, in my perfect vision it will be available locally where you use the end product. So, then of course, you need to upgrade it and process it, but there are quite few people active in this field. CO2 captured at the location itself and transformed into new value destinations would be a truly circular vision.

What about the economic competitiveness and scalability of these applications?

In terms of economic competitiveness, we are still in a research phase. For the process, you need to buy olivine but for the CO2 you’ll get the money because you are storing it. Typically lime is sold at 100 euro per ton. For applications in paper, we need to buy 2 tons of olivine (around 30-40 euro per ton, depending on logistics), 1 ton of CO2—which we get money for—and then there are processing costs. You can sell it for 300 euro per ton, so it’s a good margin between your feedstock and your output.

CO2 paper

In terms of scalability, olivine is currently mined 10 million tons per year globally. To make paper in Europe, we’ll consume 4 million tons, but that can be scaled because there is plenty of olivine available. The quantity of CO2 available is not a problem neither, that’s why we are talking about this innovation in the first place. The main point is that the equipment should be able to manage that, and part of our current research is focused to set up in place a process that can continuously process the feedstock. In that way, we can scale up much faster. As you can imagine, building a continuous chemical reactor is quite expensive, so we need to adapt other technologies to our process. This is a long process, for which we need funding and interest from industrial partners. The next phase will cost around 4 million euro, that’s a lot of money for a startup. But it’s required to prove that this process works at scale.

FUTURE PLANS

I would like to have one industry partner for each of three applications—paper, polymer and concrete—both for money and guidance, and answering together questions like: is this powder valuable for the application? Or should we make it smaller? I know, for instance, that for paper we should make it more white - we need to get this knowledge to finetune the process. And secondly, we are looking for investors to put risk money into the next development phase. In the team, now it’s mainly me, I got a network of people helping me, but to scale I realised a need a team of 3-4 people that can work full-time on the project. I believe that climate change and the need for CO2 capture and storage will get more attention to this type of innovation.

“I believe that climate change and the need for CO2 capture and storage will get more attention to this type of innovation”

VISION FOR THE DECADE OF ACTION

When we were talking about CO2 as a feedstock ten years ago, people found it an awkward expression and didn’t see any need for that. Now more people realize the need to remove the CO2 from the air - that’s very positive. When it comes to CO2 utilization, however, almost all are using CO2 for fuels and chemicals, which will ultimately be burnt at the end of the day, and release CO2 again. This makes sense from a chemical perspective, but not from a circular economy one. With paper, instead, we can make CO2-neutral paper. I am convinced that CO2 utilization for these applications will get more attention, and people will be talking about CO2 based as they now talk about bio-based. CO2-based products replacing existing products will also achieve great interest from industrial players.

The process

September 2020

A conversation between Pol Knops & Emanuele Di Francesco